- Volume 4 (2021), Issue 2

- Vol. 4 (2021), No. 2

- >

- Pages 68 - 71

- pp. 68 - 71

- Back

REACH Restriction Concerning the Use of Diisocyanates

I. Introduction

The main goal of the REACH Regulation (Regulation EC/1907/2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals) is to improve the protection of human health and the environment through the better and earlier identification of the intrinsic properties of chemical substances while enhancing innovation and competitiveness of the EU chemicals industry.

The Restriction of chemicals (together with the Registration, Authorisation and Evaluation) is one of the four processes foreseen in REACH to protect human health and the environment from unacceptable risks posed by chemicals. Restrictions may limit or ban the placing on the market or use of a substance. Conditions for the placing on the market of substances can apply to both, domestic production and imports as well as for substances in articles.

On 4 August 2020, a new regulatory restriction adopted by European authorities under REACH was published in the Official Journal of the European Union (OJ)1. The restriction established that diisocyanates cannot be used as substances on their own, as constituents in other substances or in mixtures for industrial and professional use(s) after 24 August 2023, unless the concentration of diisocyanates individually and in combination is less than 0.1 % by weight, or certain training and labelling requirements are complied with.

All diisocyanates are known as sensitisers and are classified as Resp. Sens. 1, either as a harmonised classification or as self-classification by the suppliers.

This restriction on diisocyanates requires training prior to use for adhesives and sealants containing polyurethane. The restriction established that, as of 24 August 2023, successfully completed training will be required for all professional and industrial users of products with a total monomeric diisocyanate concentration of > 0.1%. The training does not amend existing health and safety requirements but is additional to them. The restriction also dictates that certain labelling and information requirements have to be complied with.

The new regulation applies only to professionals and industry; a separate restriction for consumer use came into force several years ago. Methylene diphenyl diisocyanate (MDI)2 and some of its isomers have not been able to be placed on the market since 27 December 2010, as a constituent of mixtures in concentrations equal to or greater than 0.1 % by weight of MDI for supply to the general public, unless suppliers shall ensure before the placing on the market that the packaging contains protective gloves and is marked visibly, legibly and indelibly to inform consumers about sensitisation, dermal and inhalation risks.3

The restriction covers all these diisocyanates, as well as other substances which contain residual diisocyanates. This includes prepolymers, oligomers and polymers of diisocyanates which still contain more than 0.1 % free diisocyanates.

II. What are Diisocyanates and How are They Used?

Diisocyanates are basic components of polyurethane (PU), used in the manufacture of many different products including adhesives and sealants. Polyurethane adhesives and sealants, in turn, are versatile, innovative and safe. They are used in a wide variety of applications: construction, packaging, automotive, furniture, engineering, marine, transportation and many more. Diisocyanates are a group of chemicals containing two isocyanate functional groups (R–N=C=O) in otherwise varied structures. Due to the functional groups, all diisocyanates induce similar health effects, and are potent skin and respiratory tract sensitisers.

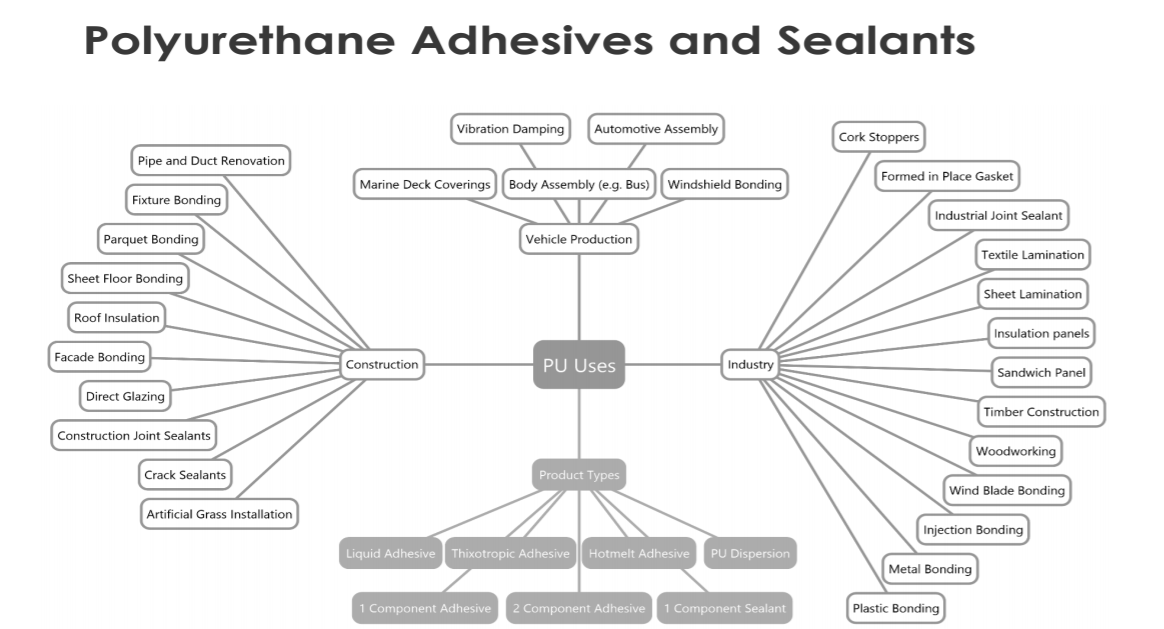

Diisocyanates are widely used in different applications in industry, most notably in the manufacturing of polyurethanes (that are used for various purposes) and as hardeners in industrial paints, glues, varnishes and resins. Moreover, diisocyanates are used in adhesives and sealants across a diverse set of markets and applications as a result of the performance advantages they bring, as illustrated in the graph.

Diisocyanate-containing products are in many of the above examples the only, or the preferred, products for their applications. Polyurethanes cannot be produced without aromatic or aliphatic diisocyanates. Therefore, there is currently no commercially viable alternative to MDI, TDI4, HDI5, IPDI6 or H12MDI7 and others. Competitive technologies have not been found to be able to reproduce polyurethane properties in most of the respective articles.

As is the case with any substance, the use of diisocyanates is safe when chemicals are handled according to relevant risk management and safety measures. It is also important to stress that no diisocyanates can be found in finished articles. Diisocyanates are used only as reactive chemicals; they react with the polyol to form the PU product and are used up during the reaction.

The diisocyanates restriction is targeted at avoiding the unsafe handling of diisocyanates, not at restricting product availability. Because of their unique properties in many applications, polyurethane adhesives and sealants will remain widely available.

1. Labelling and Information Provision

As of 24 February 2022, PU products intended to be used in industrial or professional settings with a total monomeric diisocyanate concentration of > 0.1% shall include the following phrase on their packaging: 'As of 24 August 2023, adequate training is required before industrial or professional use of this product’. The legal text does not provide further information on the labelling requirements, such as size or location, language requirements, inner/outer packaging rules, small containers, etc.

Since labelling changes need to be implemented in advance, FEICA, the Association of the European Adhesive & Sealant Industry, strongly urges its membership to start adapting labels immediately to comply with the mentioned requirement.

Furthermore, end users of polyurethane products should be provided with information on the training on the safe use of diisocyanates. However, instructions on how suppliers must provide end users with information are not provided in the restriction text. To facilitate adhesive and sealant companies to comply with the information provision requirement, a FEICA information webpage has been created to provide users with additional information on the training and will be updated regularly. The link to this webpage (or the QR code) can be added to adhesives and sealants labels. Once training materials are available, a link to the training platform will be added to the webpage. This will allow end users of adhesives and sealants to stay informed about the training development and access the training when it is available.

2. Training

By 24 August 2023, users shall have successfully completed training on the safe use of diisocyanates prior to the use of the substances or mixtures. In line with the requirements laid down in the restriction, the training content will vary depending on the application’s risk.

There are three levels of training corresponding to levels of risk. The first level of training concerns staff involved in professional uses. In this case, training entails a host of subjects including, for example, risks of exposure (e.g., dermal contact and inhalation), safety (e.g., personal protective equipment and ventilation), and proper handling (e.g., critical handling stages, and cleaning and leakages). The second level concerns staff involved in industrial applications at room temperature. Here there will be additional training for, for example, management of change, and risk in relation to the application process used. The third level of training, then, concerns staff involved in applications at high speed or over 45 °C. This additional training concerns, for example, open handling of hot or warm formulations (> 45 °C). It should be noted that managers will also have to be trained.

A consortium comprised of the diisocyanates manufacturers, the European Diisocyanate & Polyol Producers Association (ISOPA)8 and the European Aliphatic Isocyanates Producer Association (ALIPA)9, as well as several downstream user associations including FEICA, are planning to make training available online for easy usability. Additionally, the training material will be available for individual classroom training. Training material for use by FEICA members and by adhesive or sealant users will become available by mid of 2022 in all official EU languages.

Holding a certification to prove attendance at the training, including passing a final exam, will be mandatory for all professional and industrial users of the product. The training must be renewed every five years. The adopted legal text requires the training to be provided by an expert in Occupational Health & Safety. Employers must keep records of the training provided to their employees.

The diisocyanates restriction legal text does not require Member States to implement any additional measures. However, it states that the training shall comply with the provisions (existing or new) set by the Member State in which the industrial or professional user operates.

IV. Conclusion

Industry experience already shows that training is the most effective Risk Management Measure to reduce the already low number of occupational asthma cases from exposure to diisocyanates. This restriction including training obligations will be particularly important to raise awareness among workers of the sensitisation risks from both inhalation and dermal exposure to diisocyanates. The restriction will complement existing efforts to protect workers from exposure to diisocyanates under OSH legislation and provide a level playing field for industry across Europe.

The established mandatory certification system will reduce the administrative burden of checks and inspections to be carried out by Member State authorities. Harmonised training will be fully monitorable and enforceable.

Finally, the implementation of the diisocyanates restriction highlights the need to improve the interface between REACH and OSH legislation10. Industry sees diisocyanates as a good opportunity to put this objective into practice. Restrictions based on training obligations could also be the most appropriate Risk Management Measure for other substances. The upcoming revision of REACH as foreseen in the Chemical Strategy for Sustainability could be a unique opportunity to consider this matter.

It should be noted as well, that the restriction is a much more proportionate regulatory management option compared to the REACH Authorisation process, because it achieves the objective to protect human health and the environment without establishing a fairly burdensome process for downstream users, and their suppliers.

Additional information on the safe use of diisocyanates can be found on the FEICA website.11

Fig 1. Uses of PUR Adhesives and Sealants (Source: FEICA PU restriction and OELs Taskforce)

Fig 1. Uses of PUR Adhesives and Sealants (Source: FEICA PU restriction and OELs Taskforce)

Notes

[1] COMMISSION REGULATION (EU) 2020/1149 of 3 August 2020 amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) as regards diisocyanates

[3] Commission Regulation (EC) No 552/2009 of 22 June 2009 amending Regulation (EC) No 1907/2006 of the European Parliament and of the Council on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) as regards Annex XVII

[8] See, <https://www.isopa.org/>

[9] See, <https://www.alipa.org/>